350mm Diamond Saw Blade: Performance Characteristics, Applications, and Selection Guide

In industries such as stone processing, concrete cutting, and road construction, 350mm diamond saw blades are among the most widely used cutting tools due to their high cutting efficiency, strong wear resistance, and wide applicability. As a medium-sized product between small handheld saw blades and large industrial saw blades, the 350mm saw blade balances cutting depth and flexibility, making it a common choice for professional construction workers.

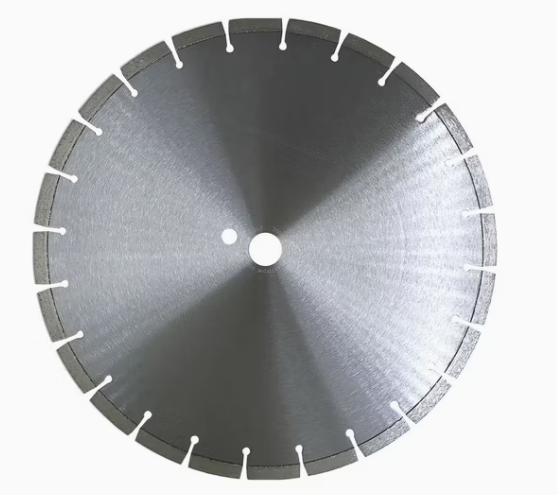

I. Structural Components of a 350mm Diamond Saw Blade

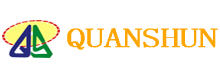

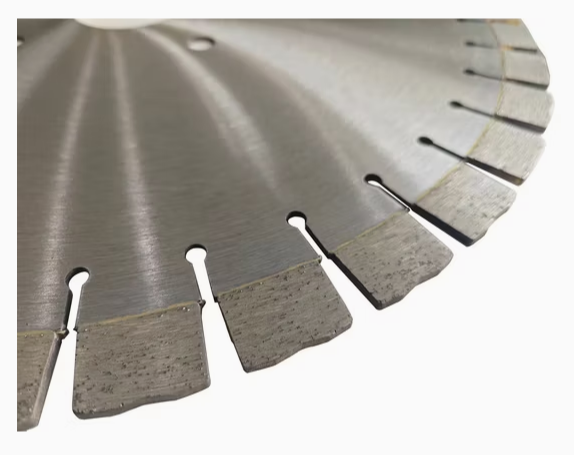

A high-quality 350mm diamond saw blade mainly consists of the following parts:

1. Steel Core (Blade Core): Made of high-strength alloy steel, it maintains the structural stability of the saw blade and withstands the tensile and impact forces under high-speed rotation.

2. Diamond Segment: The diamond segment is made of synthetic diamond particles sintered with metal powder and is the core component of the saw blade's cutting performance. Its concentration, particle size, and binder hardness directly affect the cutting speed and service life.

3. Welding Technology: Common processes include laser welding and silver soldering. Laser-welded blades are stronger, more heat-resistant, and safer, suitable for dry cutting; silver soldering is mostly used for wet cutting, and the diamond section is easier to keep sharp.

II. Main Application Areas of 350mm Diamond Saw Blades

1. Construction Engineering: Suitable for cutting concrete, cement components, bricks, building ceramics, etc.

2. Stone Processing: Commonly used for cutting and trimming granite, marble, quartz, and other slabs.

3. Road and Municipal Construction: Can be used for grooving and repairing asphalt and concrete roads.

4. Metal and Composite Materials Industry: Some specially formulated saw blades can be used to cut hard and brittle materials such as fiberglass and cast iron.

III. Classification of 350mm Diamond Saw Blades

1. By Cutting Method:

Dry Cutting Saw Blades: No water required, suitable for portable power tools, high heat dissipation required.

Wet Cutting Saw Blades: Require water supply during use, better cooling effect, more stable cutting, and longer lifespan.

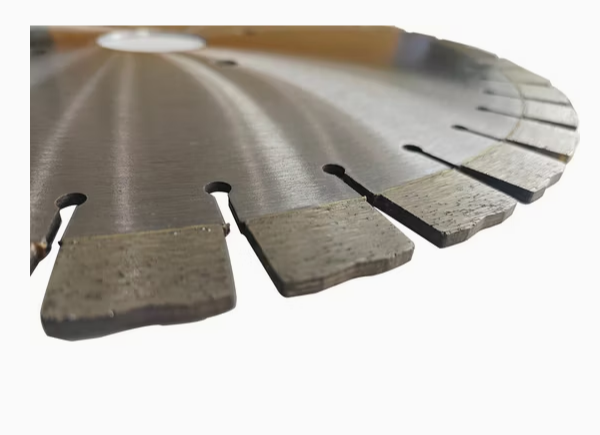

2. By Blade Shape:

Continuous Rim: Provides a clean, smooth cut, suitable for precision cutting.

Segmented: Dissipates heat quickly, suitable for high-speed cutting of hard materials.

Turbo Rim: Combines speed and smoothness, suitable for a wide range of applications.

3. By Material Formula:

Concrete-Specific

Stone-Specific

General Purpose

Asphalt-Specific

Different blade formulas determine the objects they can cut and their lifespan.

IV. How to Choose the Right 350mm Diamond Saw Blade?

1. Selection Based on Cutting Material:

Different materials have different hardness and structures, requiring different diamond concentrations and bond hardness in the blade:

Hard Materials (Granite, Reinforced Concrete): Choose a soft-bonded saw blade to ensure sharpness.

Soft Materials (Asphalt, Sandstone): Choose a hard-bonded saw blade for better wear resistance.

2. Consider Equipment Compatibility

Check the saw blade's:

Inner bore diameter (commonly 25.4mm)

Maximum speed (e.g., 4500–6000 RPM)

Cutting method (dry/wet)

Ensure compatibility and safety with your cutting machine.

3. Emphasize Product Quality and Brand Reputation

High-quality saw blades have evenly distributed blade tips, strong welds, low vibration during cutting, and a long lifespan. Choosing a well-known brand can reduce usage risks and improve efficiency.

4. Consider Cost and Lifespan

High-quality saw blades, although more expensive individually, offer faster cutting speeds, less wear, and better long-term cost-effectiveness.

V. 350mm Diamond Saw Blade Usage and Maintenance Recommendations

1. Pre-use Inspection

Ensure the blade tip is free of detachment and cracks; the base material is free of deformation.

2. Choose the Appropriate Cutting Method

Use wet cutting whenever possible to extend blade tip life and reduce dust.

3. Control Cutting Pressure and Speed

Avoid excessive pressure that could cause blade tip burning or base material deformation.

4. Regular Dressing: When the saw blade becomes dull, it can be repaired by cutting soft abrasive materials (such as sand bricks).

350mm diamond saw blades play an irreplaceable role in construction, stone processing, and road construction due to their powerful cutting capabilities and wide applicability. Choosing a stable and adaptable saw blade can not only improve work efficiency but also reduce equipment wear and construction costs. Through proper selection and use, the optimal performance of a 350mm diamond saw blade can be fully realized.

300mm Professional Diamond Saw

300mm Professional Diamond Saw

Laser Welded Diamond Saw Blade

Laser Welded Diamond Saw Blade

350mm 400mm Silent Silver Braz

350mm 400mm Silent Silver Braz

350mm Diamond Saw Blade: Perfo

350mm Diamond Saw Blade: Perfo